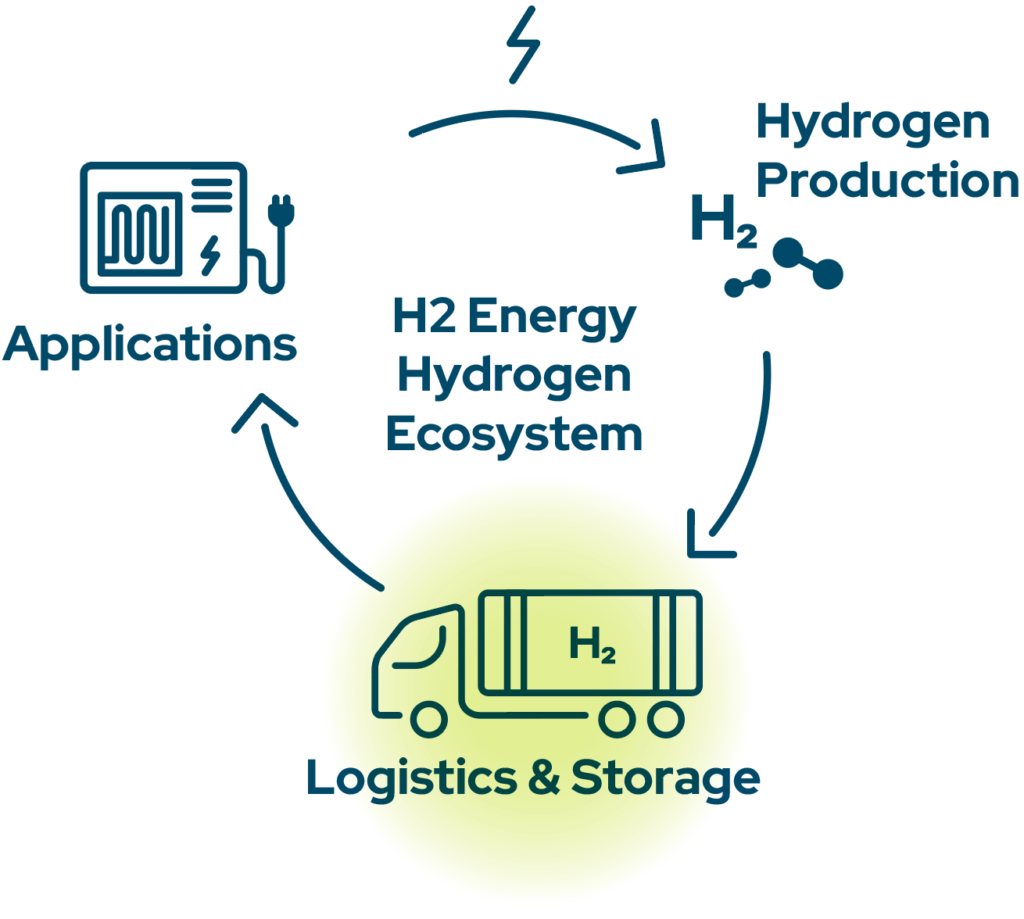

Smart hydrogen storage and logistics solutions

Developed and optimized for the Swiss green hydrogen ecosystem, the containerized logistics solution used by Hydrospider is available for your project as well. Combining pressurized storage containers, convenient docking stations and easy to use interfaces, the entire end to end logistics solution has been designed for real world operation with efficiency and safety in mind.

Compared to legacy tube trailers with manual interfaces which rely on trained technician oversight, the smart hydrogen storage and logistics solution from H2 Energy allows drivers to perform all operations in short intervals. This reduces the cost and complexity of moving hydrogen from point A to B or between a network of producers and off-takers within a hydrogen ecosystem.

How it works

Watch a video of a container dropoff

Our optimized logistic concept

Key advantages

- Optimised logistics concept

Container exchange in 15 minutes thanks to smart and efficient docking station / filling panel - All handling done by driver

- Filling panel to check MEGC keydata, leak test, hose flushing

- Controlled filling speed

- Automated operation

- Integrated safety functions

MEGC container on secure docking station

Interface Panel for filling/emptying containers

Efficient H2 delivery

Storage containers

The 20 ft Multiple Element Gas Container (MEGC) is an advanced hydrogen storage and logistics solution from 38MEGAPASCAL, a company of H2 Energy. FORVIA and H2 Energy have joined forces to develop an innovative H₂ storage container for the safe transportation of pressurised hydrogen. The container is certified for ADR and RID applications and can be seamlessly integrated into any efficient logistics system.

Hydrogen storage containers serve both as on-site storage and as a means of transport. This avoids the need for costly, fixed storage tanks and eliminates time-consuming and expensive gas transfers from trailers to local storage tanks. Furthermore, they ensure the immediate availability of high-pressure hydrogen without the initial need for additional compression.

The 20 ft ISO-compatible container can store 465 kg of hydrogen at 380 bar. Containers will be available for order from the second half of 2025. A 40 ft version with a capacity of nearly 1 ton is also planned.

Specifications 1 | Unit | 20 ft MEGC | 40 ft MEGC |

|---|---|---|---|

Working pressure 2 | bar | 380 | 380 |

H2 capacity (total) | kg | 465 | 950 |

# of banks | 3 | 3 | |

# of cylinders | 48 | 98 | |

Cylinder type 3 | III | III | |

Cylinder manufacturer | FORVIA | FORVIA | |

Gross weight | t | < 14 | < 28 |

Dimensions (W × L × H) | m | 2.5 x 6.1 x 2.7 | 2.5 x 12.1 x 2.7 |

Interface Panels

The brain of H2 Energy’s smart hydrogen logistics solution, the proprietary filling and emptying interface consist of a customized container manifold and dedicated panels. Consisting of a bi-directional hydrogen supply line and a container interface connector (multiplug), this solution allows for the fast and easy exchange of containers which can be performed by the driver who picks up and drops off the containers.

Docking stations

Docking stations provide secure and defined placement of hydrogen storage containers for production sites, refueling stations and other off-takers. They allow for safe and efficient deliver and pickup and are available for both 20- and 40-foot containers. Compared to a trailer or container on a chassis solution, a swap container on a docking station provides maximum safety by minimizing points of failure or potential ignition sources in the vicinity of the hydrogen storage.

Want to learn more?

Are you interested in hydrogen storage and logistics solutions?

Contact us for more information today.